WORLDWIDE

News

Home > News > Latest News

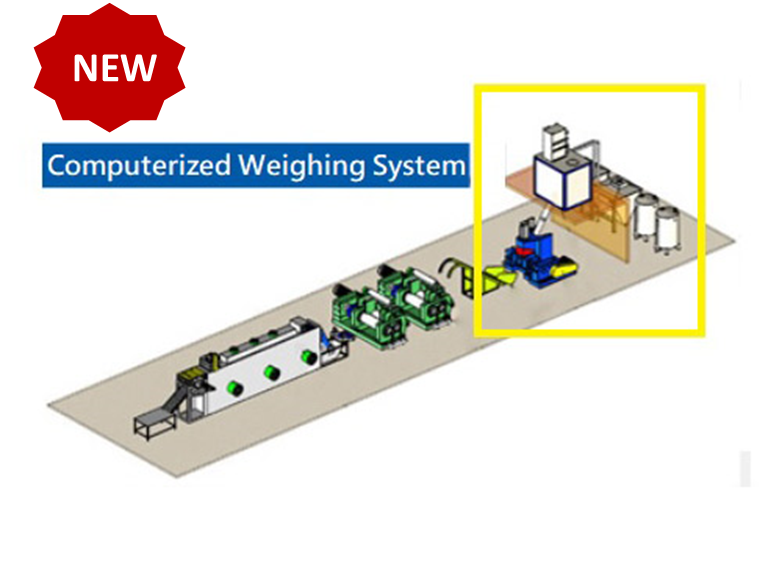

New: Computerized weighing system for compounding dose

2020/11/13

This computerized weighing system helps upgrade our working efficiency and product quality, and the most important thing is to improve the working environment and protect employees’health.

The benefit of the computerized weighing system –

- Better working environment: Carbon black & inorganic fillers, greases are transferred by the negative pressure conveying system & stainless pipes during dosing phase, this helps reduce the spread of pollutive dusts in the working environment.

- Saving of manpower and time: the feed of filler doses are now by automation system instead of manpower, which shorten the working time.

- High efficiency: increase the accuracy of the dosing work (+/-200gr) which helps enhance the stability & quality of product, and the error-proof detecting system also help eliminate material waste and human error.

- Easy to operate: with modular that can easily set when new product and formula is added.

- Easy to manage: the fillers and greases are well stored in independent tanks with their product name and barcode labelled on.

- Traceability of dosing: each dosing process are recorded and can be traced in time.

- High safety standard: comply with current labor safety regulations and meet our goal of improving employees' health.